Researchers have developed a phase-transformable membrane that efficiently separates gases like CO2 and H2 by shifting between liquid, glass, and crystalline states.

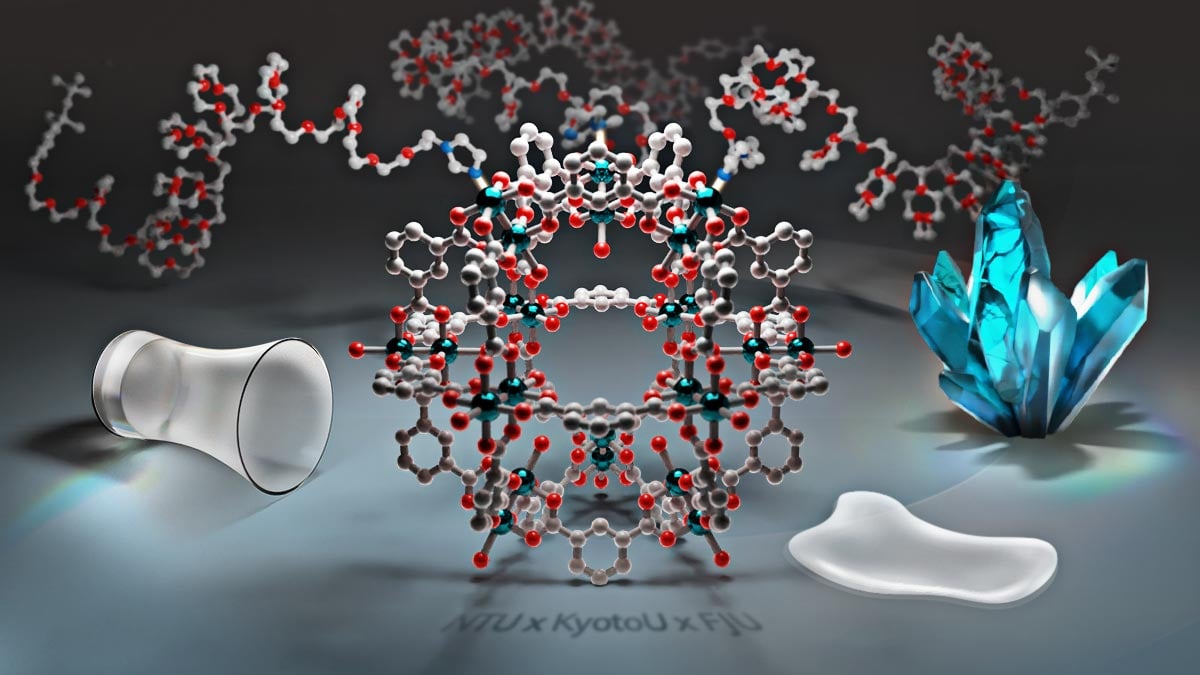

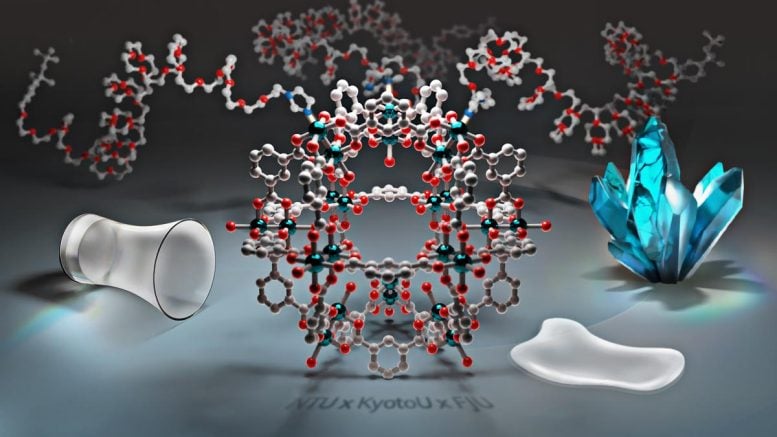

This innovative technology, leveraging metal-organic polyhedra and polyethylene glycol, promises enhanced selectivity and permeability, potentially transforming industrial gas separation for environmental protection and clean energy production.

Gas Separation Challenges

Industrial gas separation is crucial for advancing clean energy and protecting the environment, yet it requires materials that are both efficient and adaptable. Current materials fall short in their ability to selectively separate gases like carbon dioxide (CO2) and hydrogen (H2) without significant energy costs. Addressing this challenge, researchers at Kyoto University’s Institute for Integrated Cell-Material Sciences (WPI-iCeMS) and National Taiwan University’s Department of Chemical Engineering have developed a groundbreaking phase-transformable membrane that could meet these demands.

Advancements in Membrane Technology

This innovative membrane combines metal-organic polyhedra (MOP) with polyethylene glycol (PEG) chains. Professor Shuhei Furukawa of Kyoto University, who led the team, explains, “Traditional solid membranes are effective but limited in flexibility, which hinders their efficiency in industrial settings.” The team’s phase-transformable porous materials, however, can be precisely tuned for gas permeability and selectivity by altering the material’s physical state. Through temperature control, the membrane can shift between liquid, glass, and crystalline states, tailoring its permeability and selectivity for specific gases and enhancing efficiency.

Enhancing CO2 Capture and Hydrogen Purification

The membrane’s liquid phase is particularly effective for CO2 capture. In this state, it demonstrates high permeability and selectivity, enabling it to capture CO2 efficiently from the hydrogen mixture and potentially reduce energy use in capture processes. This characteristic positions it as a promising solution for reducing industrial CO2 emissions and supporting clean energy production through hydrogen purification.

The versatility of this phase-transformable membrane opens up new possibilities for customizable gas separation. The team envisions a range of applications in which the membrane can be adapted to specific conditions by carefully selecting MOP structures and polymers to fine-tune its properties. This adaptability could allow industries to selectively target various gases under different environmental conditions.

Scaling Up and Broader Applications

“The next challenge is scaling up production to make this membrane technology feasible for large-scale applications,” says Professor Dun-Yen Kang at National Taiwan University. The team is also investigating combinations between MOPs and polymers to widen the scope of gases that can be effectively separated. With further development, this innovative membrane could become a cornerstone in sustainable energy solutions, helping industries meet environmental standards while improving efficiency.

Reference: “Phase-transformable metal-organic polyhedra for membrane processing and switchable gas separation” 13 November 2024, Nature Communications.

DOI: 10.1038/s41467-024-53560-3