Tungsten, the preferred material for tokamak fusion reactors, poses challenges due to sputtering that cools plasma, making fusion hard to sustain.

Researchers at PPPL suggest that sprinkling boron powder into tokamaks could prevent this by shielding walls and preventing tungsten entry into the plasma. Recent experiments across global tokamaks and a new computer model support the potential of boron powder in maintaining optimal plasma conditions for fusion.

Tungsten and Fusion Challenges

Fusion researchers are increasingly favoring tungsten as the ideal material for components that directly face the plasma inside fusion reactors, such as tokamaks and stellarators. However, under the intense heat of fusion plasma, tungsten atoms can sputter from the reactor walls into the plasma. Excessive tungsten cools the plasma significantly, posing a challenge to sustaining fusion reactions.

Researchers at the U.S. Department of Energy’s Princeton Plasma Physics Laboratory (PPPL) now have experimental evidence indicating that introducing boron powder into the tokamak could address this issue. Boron partly shields the reactor walls from the plasma and prevents wall atoms from contaminating it. Moreover, a new computer modeling framework developed by PPPL researchers suggests that the boron powder may only need to be applied from a single point. These findings and the new modeling approach were recently showcased at the 66th Annual Meeting of the American Physical Society Division of Plasma Physics in Atlanta.

Boron Solution in Action

Joseph Snipes, deputy head for Tokamak Experimental Science, is optimistic about the solid boron injection system based on experiments that demonstrated reduced tungsten sputtering after a solid boron injection. The experiments were conducted in three tungsten-walled tokamaks worldwide: one in Germany, one in China and one in the U.S.

“The boron is sprinkled into the tokamak plasma as a powder, like from a saltshaker, which is ionized at the plasma’s edge and then deposited on the tokamak’s inner walls and the exhaust region,” he said. “Once coated with a thin layer of boron, it will stop the tungsten from getting into the plasma and radiating away the plasma energy.”

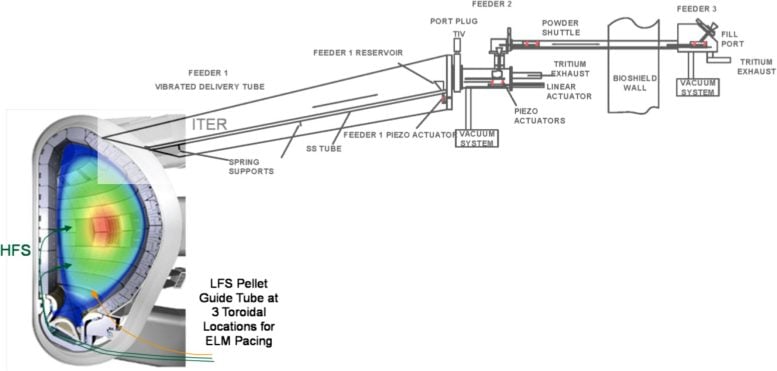

Snipes and his colleagues are working on the boron injection system with the ultimate goal of potentially using it in the ITER Organization’s reactor-scale tokamak. The injection system is well suited to the task, as it can add boron while the machine is operating. It can also precisely control and limit the amount of boron injected. The deposited boron layers retain the radioactive element tritium, which must be minimized in the ITER tokamak to comply with nuclear safety. Scientists and engineers from ITER and the Oak Ridge National Laboratory also collaborated on this project.

Advancements in Boron Injection Modeling

Florian Effenberg, a staff research physicist at PPPL, led a separate project to create a computer modeling framework for the boron injection system in the DIII-D tokamak. The framework suggests that sprinkling the boron powder from just one location may provide a sufficiently uniform distribution of boron across the reactor components considered in the simulation domain.

“We’ve developed a new way to understand how injected boron material behaves in a fusion plasma and how it interacts with the walls of fusion reactors to keep them in good condition while they are operating,” said Effenberg.

Next Steps and ITER Considerations

The researchers’ approach combines three different computer models to create a new framework and workflow. “One model simulates the behavior of the plasma, another shows how the boron powder particles move and evaporate in the plasma, and the third examines how the boron particles interact with the tokamak walls, including how they stick, wear away and mix with other materials,” Effenberg said.

“These insights are crucial for optimizing boron injection strategies to achieve effective and uniform wall conditioning in ITER and other fusion reactors,” Effenberg said.

While the modeling framework looked at DIII-D, a tokamak operated by General Atomics in San Diego, the next phase of this research involves scaling the modeling framework to ITER. While DIII-D’s walls are made of carbon, ITER plans to have tungsten walls, so it will be important to research any differences in how the boron protects the walls.

Meeting: Annual Meeting of the American Physical Society Division of Plasma Physics

The following researchers also contributed to the work described by Snipes: Larry Robert Baylor, Alessandro Bortolon, Florian Effenberg, Erik Gilson, Alberto Loarte, Robert Lunsford, Rajesh Maingi, Steve Meitner, Federico Nespoli, So Maruyama, Alexander Nagy, Zhen Sun, Jeff Ulreich and Tom Wauters. Funding for this work was provided by the ITER Organization.

Klaus Schmid, Federico Nespoli, and Yühe Feng worked on the modeling framework described by Effenberg in this release. Alessandro Bortolon, Jeremy Lore, Tyler Abrams, Brian Grierson, Rajesh Maingi, and Dmitry Rudakov contributed to the application of that modeling framework. The work was completed with funding from DE-AC02-09CH11466, DE-FC02-04ER54698, and DE-AC05-00OR22725.