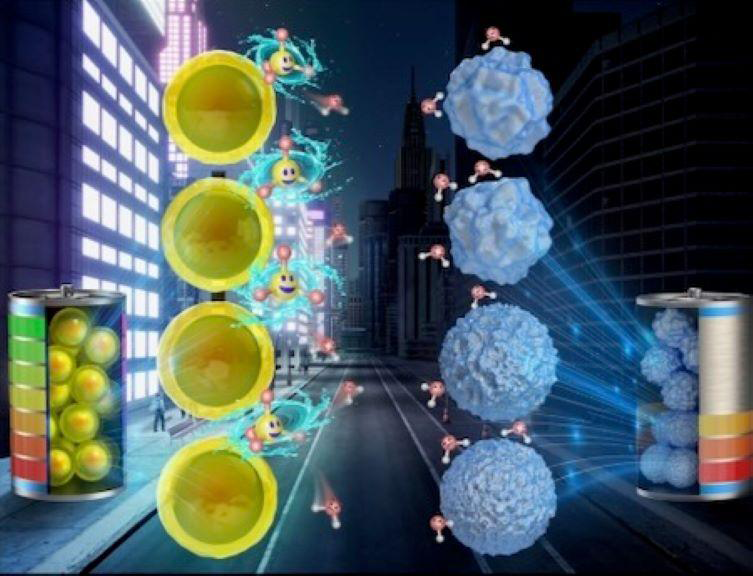

A WPI research team has improved iron-based alkaline batteries by adding silicate, preventing hydrogen gas formation during charging.

The world is swiftly shifting toward renewable energy, but challenges remain. Solar power is unavailable at night, and wind energy fluctuates unpredictably. To address these gaps, new technologies are needed to store excess energy from the grid when production is high and release it during times of shortage.

Rechargeable lithium-ion batteries play a crucial role in everyday life, powering devices from smartphones to electric vehicles. However, they rely on limited resources like lithium, nickel, and cobalt, raising concerns about sustainability and cost.

Xiaowei Teng, the James H. Manning Professor in Chemical Engineering at WPI, is leading a team to explore new battery technologies for grid energy storage. The team’s recent results, published in the European scientific journal ChemSusChem, suggest that iron, when treated with the electrolyte additive silicate, could create a high-performance alkaline battery anode.

The second most abundant metal in the Earth’s crust after aluminum, iron is far more sustainable than nickel and cobalt. The United States alone recycles approximately over 40 million metric tons of iron and steel from scrap each year.

Teng notes that iron is already used as an alkaline battery anode in iron-nickel alkaline batteries—invented by Thomas Edison in the 1900s—but it has low energy efficiency and storage capacity due to the formation of hydrogen gas during charging and inert iron oxide during discharging.

The Role of Silicate in Iron Alkaline Batteries

“You don’t want hydrogen gas formation when charging a battery,” said Teng. “It impairs the energy efficiency of the battery system considerably. Without addressing these technical challenges, iron alkaline batteries are less attractive for modern energy storage systems to be coupled with electric grids.”

In an Oct. 7 cover story featured in ChemSusChem, the team reported that adding silicate to the electrolytes allowed them to charge a battery without producing hydrogen.

A chemical compound of silicon and oxygen, silicate has long been used as an inexpensive and simple agent in glass, cement, insulation, and detergents, said Sathya Jagadeesan, a PhD student at WPI and lead author on the paper. The team discovered that silicate also strongly interacts with battery electrodes and suppresses hydrogen gas generation. Teng said this new process could improve the alkaline iron redox chemistries in iron-air and iron-nickel batteries for energy storage applications, such as microgrids or individual solar or wind farms.

Reference: “Unlocking High Capacity and Reversible Alkaline Iron Redox Using Silicate-Sodium Hydroxide Hybrid Electrolytes” by Sathya Narayanan Jagadeesan, Fenghua Guo, Ranga Teja Pidathala, A. M. Milinda Abeykoon, Gihan Kwon, Daniel Olds, Badri Narayanan and Xiaowei Teng, 19 June 2024, ChemSusChem.

DOI: 10.1002/cssc.202400050