Using advanced X-ray techniques, scientists have achieved a significant milestone in 3D printing by producing 17-4 PH stainless steel with superior strength and durability.

This development promises to lower costs and increase production flexibility, offering profound implications for manufacturing complex materials.

Breakthrough in 3D Printing of Stainless Steel

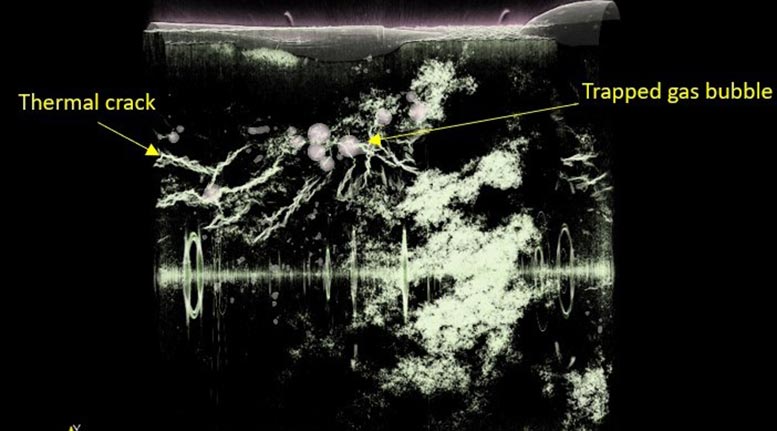

Researchers have developed a reliable method to produce a specific type of stainless steel, 17-4 PH, using additive manufacturing or 3D printing. Historically, 3D printing steel and other alloys has been problematic due to the rapid temperature changes these materials undergo when heated by the lasers in 3D printers. These fluctuations disrupt the structural arrangement of atoms, compromising the material’s toughness. By employing bright X-ray beams, scientists monitored these swift changes in real time and modified the chemical composition to counteract them, thereby enhancing the durability of the final product.

Known for its robustness and corrosion resistance, 17-4 PH stainless steel is utilized in industrial machinery, marine vessels, aircraft, and medical devices. These new advancements could enable manufacturers of 17-4 PH components to reduce costs and improve manufacturing flexibility. Moreover, the techniques developed in this study pave the way for a deeper understanding of how to 3D print various materials while enhancing their properties and performance.

Innovations in Additive Manufacturing

3D printing, also known as additive manufacturing, is a direct and integral construction of a three-dimensional object from a digital model, layer by layer. Metal alloys are particularly tricky to print in this manner due to the rapid temperature changes that occur during the process. Using 3D printing to reproduce a durable material such as 17-4 PH stainless steel requires the ability to closely monitor these rapid changes as they happen and make modifications to the material’s crystal structure.

Monitoring 3D printing of 17-4 PH stainless steel was made possible by the bright X-ray beams at the Advanced Photon Source (APS), a Department of Energy Office of Science light source user facility at Argonne National Laboratory. The researchers used high-energy X-ray diffraction to capture images every few milliseconds as the material was heated and cooled. Using these images, the team mapped the correlation between process parameter changes and modifications to the crystal structure, then used that analysis to guide alloy development for optimizing the printing process. They then used small-angle X-ray scattering at the APS to characterize tiny structural anomalies called nanoprecipitates that strongly influence the final strength of a printed stainless-steel part. The method developed will help enable manufacturers to consistently and cost efficiently produce one of the toughest materials in the world.

Reference: “Phase transformation dynamics guided alloy development for additive manufacturing” by Qilin Guo, Minglei Qu, Chihpin Andrew Chuang, Lianghua Xiong, Ali Nabaa, Zachary A. Young, Yang Ren, Peter Kenesei, Fan Zhang and Lianyi Chen, 2 August 2022, Additive Manufacturing.

DOI: 10.1016/j.addma.2022.103068

This work was funded by the National Science Foundation (NSF) and the University of Wisconsin-Madison Startup Fund and used resources at the UW-Madison Wisconsin Centers for Nanoscale Technology partially supported by NSF through the University of Wisconsin Materials Research Science and Engineering Center. The research also used resources at the Advanced Photon Source, a Department of Energy Office of Science user facility.