Georgia Tech researchers developed a new iron chloride cathode that could slash lithium-ion battery costs and revolutionize electric vehicles and energy storage.

A research team from multiple institutions, led by Hailong Chen of Georgia Tech, has developed a new, cost-effective cathode with the potential to significantly enhance lithium-ion batteries (LIBs), potentially revolutionizing the electric vehicle (EV) market and large-scale energy storage systems.

“For a long time, people have been looking for a lower-cost, more sustainable alternative to existing cathode materials. I think we’ve got one,” said Chen, an associate professor with appointments in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering.

The revolutionary material, iron chloride (FeCl3), costs a mere 1-2% of typical cathode materials and can store the same amount of electricity. Cathode materials affect capacity, energy, and efficiency, playing a major role in a battery’s performance, lifespan, and affordability.

“Our cathode can be a game-changer,” said Chen, whose team describes its work in Nature Sustainability. “It would greatly improve the EV market — and the whole lithium-ion battery market.”

First commercialized by Sony in the early 1990s, LIBs sparked an explosion in personal electronics, like smartphones and tablets. The technology eventually advanced to fuel electric vehicles, providing a reliable, rechargeable, high-density energy source. But unlike personal electronics, large-scale energy users like EVs are especially sensitive to the cost of LIBs.

Batteries are currently responsible for about 50% of an EV’s total cost, which makes these clean-energy cars more expensive than their internal combustion, greenhouse-gas-spewing cousins. The Chen team’s invention could change that.

Building a Better Battery

Compared to old-fashioned alkaline and lead-acid batteries, LIBs store more energy in a smaller package and power a device longer between charges. But LIBs contain expensive metals, including semiprecious elements like cobalt and nickel, and they have a high manufacturing cost.

So far, only four types of cathodes have been successfully commercialized for LIBs. Chen’s would be the fifth, and it would represent a big step forward in battery technology: the development of an all-solid-state LIB.

Conventional LIBs use liquid electrolytes to transport lithium ions for storing and releasing energy. They have hard limits on how much energy can be stored, and they can leak and catch fire. But all-solid-state LIBs use solid electrolytes, dramatically boosting a battery’s efficiency and reliability and making it safer and capable of holding more energy. These batteries, still in the development and testing phase, would be a considerable improvement.

As researchers and manufacturers across the planet race to make all-solid-state technology practical, Chen and his collaborators have developed an affordable and sustainable solution. With the FeCl3 cathode, a solid electrolyte, and a lithium metal anode, the cost of their whole battery system is 30-40% of current LIBs.

“This could not only make EVs much cheaper than internal combustion cars, but it provides a new and promising form of large-scale energy storage, enhancing the resilience of the electrical grid,” Chen said. “In addition, our cathode would greatly improve the sustainability and supply chain stability of the EV market.”

Solid Start to New Discovery

Chen’s interest in FeCl3 as a cathode material originated with his lab’s research into solid electrolyte materials. Starting in 2019, his lab tried to make solid-state batteries using chloride-based solid electrolytes with traditional commercial oxide-based cathodes. It didn’t go well — the cathode and electrolyte materials didn’t get along.

The researchers thought a chloride-based cathode could provide a better pairing with the chloride electrolyte to offer better battery performance.

“We found a candidate (FeCl3) worth trying, as its crystal structure is potentially suitable for storing and transporting Li ions, and fortunately, it functioned as we expected,” said Chen.

Currently, the most popularly used cathodes in EVs are oxides and require a gigantic amount of costly nickel and cobalt, heavy elements that can be toxic and pose an environmental challenge. In contrast, the Chen team’s cathode contains only iron (Fe) and chlorine (Cl)—abundant, affordable, widely used elements found in steel and table salt.

In their initial tests, FeCl3 was found to perform as well as or better than the other, much more expensive cathodes. For example, it has a higher operational voltage than the popularly used cathode LiFePO4 (lithium iron phosphate, or LFP), which is the electrical force a battery provides when connected to a device, similar to water pressure from a garden hose.

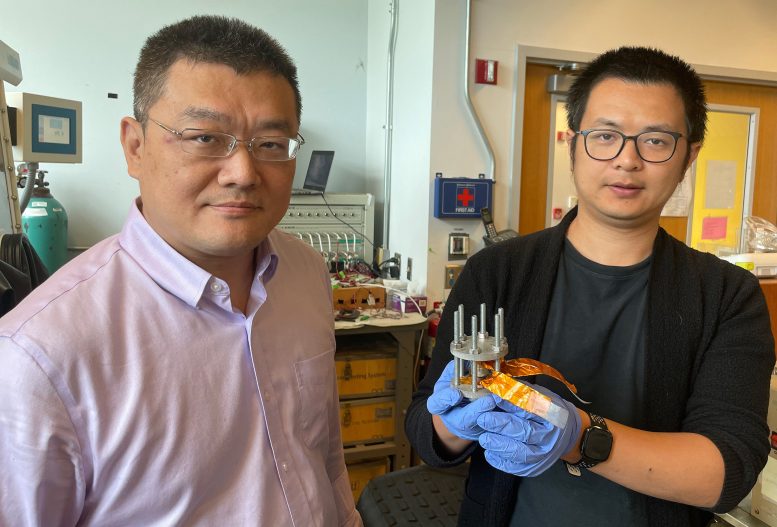

This technology may be less than five years from commercial viability in EVs. For now, the team will continue investigating FeCl3 and related materials, according to Chen. The work was led by Chen and postdoc Zhantao Liu (the lead author of the study). Collaborators included researchers from Georgia Tech’s Woodruff School (Ting Zhu) and the School of Earth and Atmospheric Sciences (Yuanzhi Tang), as well as the Oak Ridge National Laboratory (Jue Liu) and the University of Houston (Shuo Chen).

“We want to make the materials as perfect as possible in the lab and understand the underlying functioning mechanisms,” Chen said. “But we are open to opportunities to scale up the technology and push it toward commercial applications.”

Reference: “Low-cost iron trichloride cathode for all-solid-state lithium-ion batteries” by Zhantao Liu, Jue Liu, Simin Zhao, Sangni Xun, Paul Byaruhanga, Shuo Chen, Yuanzhi Tang, Ting Zhu and Hailong Chen, 23 September 2024, Nature Sustainability.

DOI: 10.1038/s41893-024-01431-6

The study was funded by the National Science Foundation (Grant Nos. 1706723 and 2108688).