A new study introduces a simplified method for producing Mo carbide catalysts that exhibit outstanding activity and stability in CO2 conversion.

This method avoids complex traditional processes, offers a new carbon cycle pathway for improved efficiency, and highlights potential for broad industrial application.

Molybdenum Carbide Catalysts

Molybdenum (Mo) carbides, known for their unique electronic and structural properties, are considered promising alternatives to noble metal catalysts in heterogeneous catalysis. However, traditional methods for preparing Mo carbides suffer from complex processes, stringent synthesis conditions, challenging crystal regulation, and high energy consumption. Additionally, Mo carbides are susceptible to oxidation and deactivation, which poses a significant barrier to their widespread application.

In a study published today (September 9) in Nature Chemistry, a research group led by Prof. Jian Sun from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) developed a facile strategy to establish Mo carbide catalysts for efficient CO2 conversion, bypassing the complicated carburization process of traditional methods.

Innovative Catalyst Fabrication Method

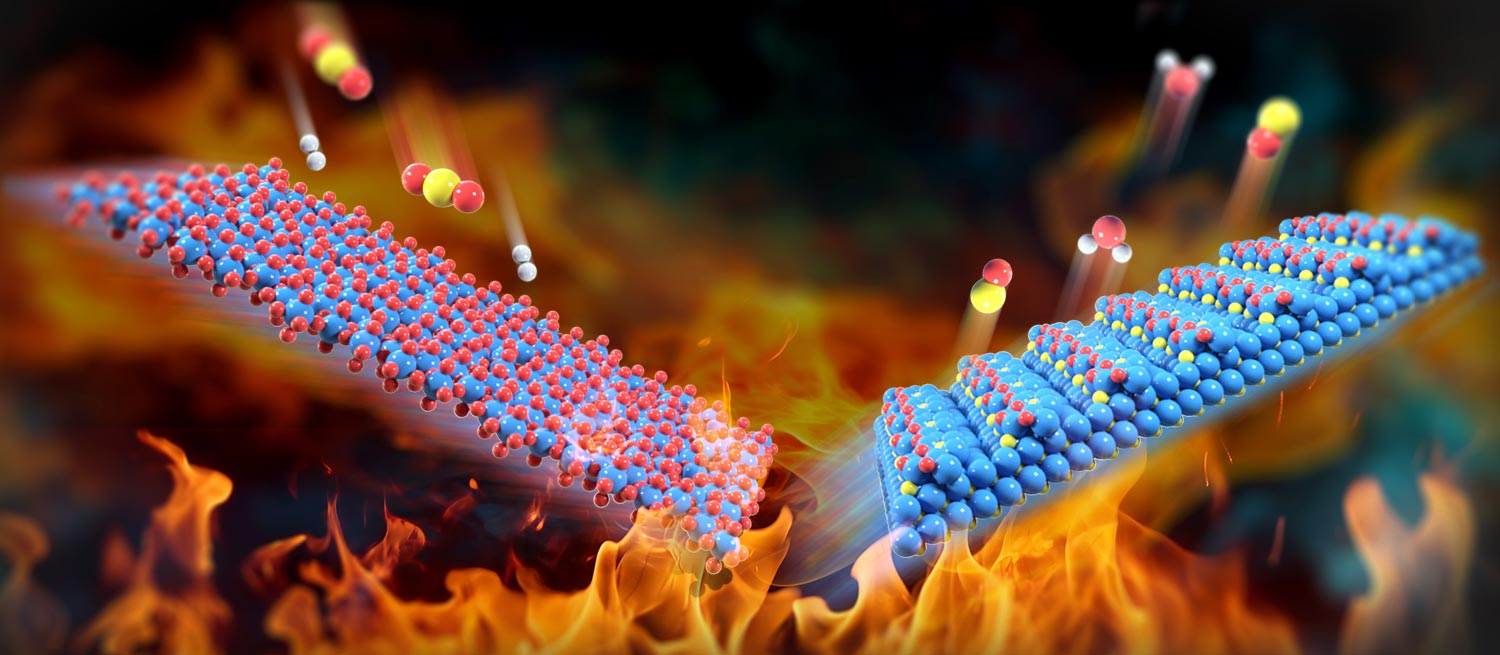

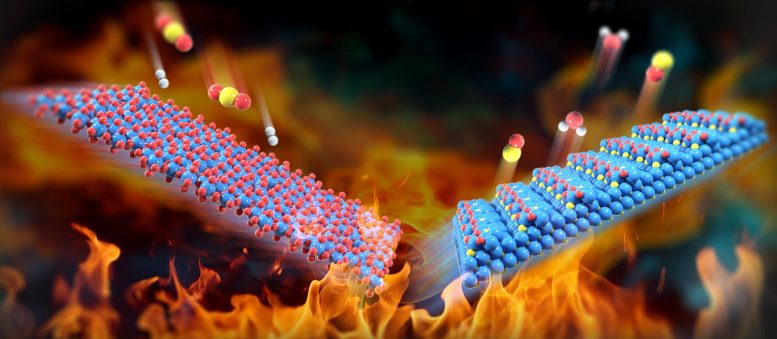

The researchers fabricated an Ir-modified MoO3 catalyst using a one-step flame spray pyrolysis (FSP) method, resulting in metastable Mo oxide species due to the rapid quenching from high temperatures. This unique structure facilitated reaction-induced carburization during the RWGS reaction, thus creating oxidation-resistant Mo oxycarbide (MoOxCy) active sites.

The catalyst exhibited excellent activity and stability, highlighting the superiority of reaction-induced Mo carbide catalysts. At 600°C, it achieved a CO production rate of 17.5 molgcat-1 h-1 with 100% CO selectivity. No significant deactivation was observed over a 2,000-hour stability test, showing its great potential for industrial applications.

Further investigation revealed that the crucial active sites in the RWGS reaction were the unsaturated MoOxCy species on the surface of Mo carbides. These species could maintain a dynamic equilibrium in the combined reduction, carburization, and oxidation atmosphere, preventing severe deactivation.

Enhancing CO2 Conversion Efficiency

Additionally, the researchers proposed a new carbon cycle pathway in the RWGS reaction that was more thermodynamically favorable than the traditional redox pathway by promoting the H2 dissociation through *COH species. This pathway could act as a supplement to the redox mechanism, enhancing CO2 conversion on Mo carbides and leading to superior catalytic performance.

“Our study provides a low energy-consuming strategy for developing Mo carbides as efficient catalysts and paves the way for the application of a low-cost Mo-based catalyst system for CO2 utilization,” said Prof. Sun.

Reference: “Reaction-induced unsaturated Mo oxycarbides afford highly active CO2 conversion catalysts” 9 September 2024, Nature Chemistry.

DOI: 10.1038/s41557-024-01628-4