Lighter vehicles can travel farther on less energy, driving demand for lighter automotive components. High-performance aluminum alloys, such as alloy 7075, are among the lightest and strongest options, but they require energy-intensive production that raises costs and therefore limits their use.

Research from the Pacific Northwest National Laboratory (PNNL) cuts that energy in half with a more efficient process to manufacture high-performance aluminum components. With support from the Department of Energy’s Advanced Manufacturing Office, researchers determined that the Shear Assisted Processing and Extrusion (ShAPE) technology can eliminate heat treatment steps in the production process, resulting in significant energy savings and reduced emissions. ShAPE is a green, affordable manufacturing approach that enables broad use of high-performance aluminum alloys in automotive applications.

A recipe for next-generation metals manufacturing

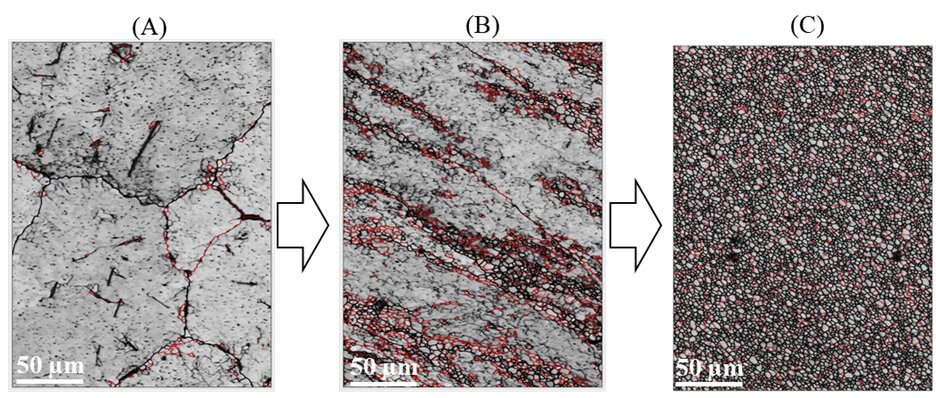

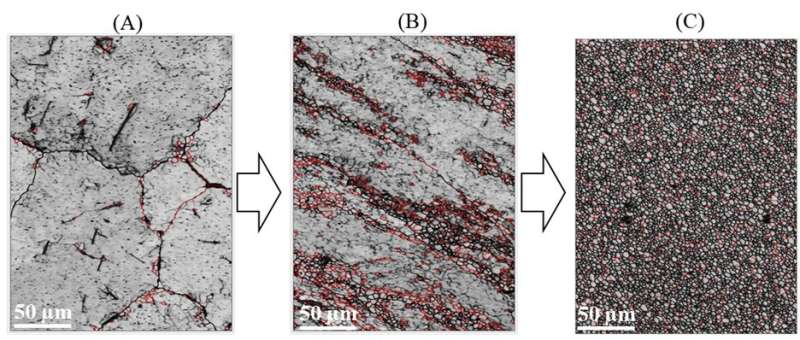

Much like baking a cake, metals manufacturing relies on well-mixed ingredients and a lot of heat. Conventional metal production uses heat to melt individual metals and alloying elements together—like aluminum, copper, or magnesium—to create alloys that are lighter, stronger, or easier to form. If these elements aren’t well-mixed, cracks and fractures can form during processing that compromise the properties of the final product—as an undermixed, lumpy cake batter will result in a crumbling, disastrous cake. In metals production, heat is used to ensure that individual metal elements in an alloy are well-mixed during a step called homogenization.

During homogenization, large metal castings called billets are heated to nearly 500 degrees Celsius—about 900 degrees Fahrenheit—for up to 24 hours. This heat treatment step dissolves alloy aggregates—akin to lumps in the cake batter—in the billet to ensure that all metal elements are evenly distributed or homogenized. This improves the performance of the final product. After homogenization, the metal rods undergo further heating and forming in a step called extrusion.

“Homogenization is the biggest energy-consuming step in the entire metals extrusion process,” said Scott Whalen, PNNL chief materials scientist and co-developer of ShAPE.

The ShAPE machine eliminates the need for separate homogenization and extrusion steps by combining heating and deformation—the change in the shape of the metal itself. In the ShAPE machine, the metal billet is simultaneously pushed through a small opening in a die which rotates. Together, the rotational movement and deformation thoroughly mixes the metal elements as they are being extruded. Essentially, the ShAPE process homogenizes the metal billet in a few seconds, immediately before it is extruded. This eliminates the need for a day-long, pre-heating homogenization step and means that no additional energy is used to heat the billet during extrusion. Together, this results in an energy savings of up to 50 percent using ShAPE.

Have your cake and eat it too

Not only is ShAPE a more energy efficient and quicker process, but it also improves how well the individual alloying elements are mixed, leading to a better final product. Like lumpy batter can ruin a cake, the final product in extrusion manufacturing often performs better when the elements are well-mixed. Performance testing showed that components made of aluminum alloys processed with ShAPE exceeded current American Society for Testing and Materials standards for strength and elongation.

“We took a closer look using an electron microscope and saw that ShAPE breaks apart the alloy aggregates and dissolves them into the aluminum matrix prior to extrusion, making it more extrudable,” said Tianhao Wang, PNNL materials scientist and lead author on the recent publication in Materials and Design. “This translates to better performance—our aluminum 7075 alloys are stronger and stretch farther before breaking.”

Putting high-performance aluminum alloys in reach

Aluminum alloys are valued in the automotive and aerospace industries because they are strong and lightweight. The most high-performance aluminum alloys are time- and energy-intensive to manufacture, pricing them out of many markets, like applications in passenger vehicles. The ShAPE process removes a major hurdle in the production of high-performance aluminum alloys by dramatically reducing energy consumption and greenhouse gas emissions during manufacturing.

“This is an important step in unlocking the potential of next-generation metals manufacturing to produce better, cheaper, greener products for the future,” said Whalen.

Researchers introduce a speedier manufacturing process for stronger aluminum alloys

Tianhao Wang et al, Extrusion of Unhomogenized Castings of 7075 Aluminum via ShAPE, Materials & Design (2021). DOI: 10.1016/j.matdes.2021.110374

Sertac Akar et al, Techno-Economic Analysis for Shear Assisted Processing and Extrusion (ShAPE) of High Strength Aluminum Alloys, (2022). DOI: 10.2172/1846614

Pacific Northwest National Laboratory

Citation:

Aluminum alloy manufacturing now 50% more energy efficient (2022, July 20)

retrieved 20 July 2022

from https://phys.org/news/2022-07-aluminum-alloy-energy-efficient.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.