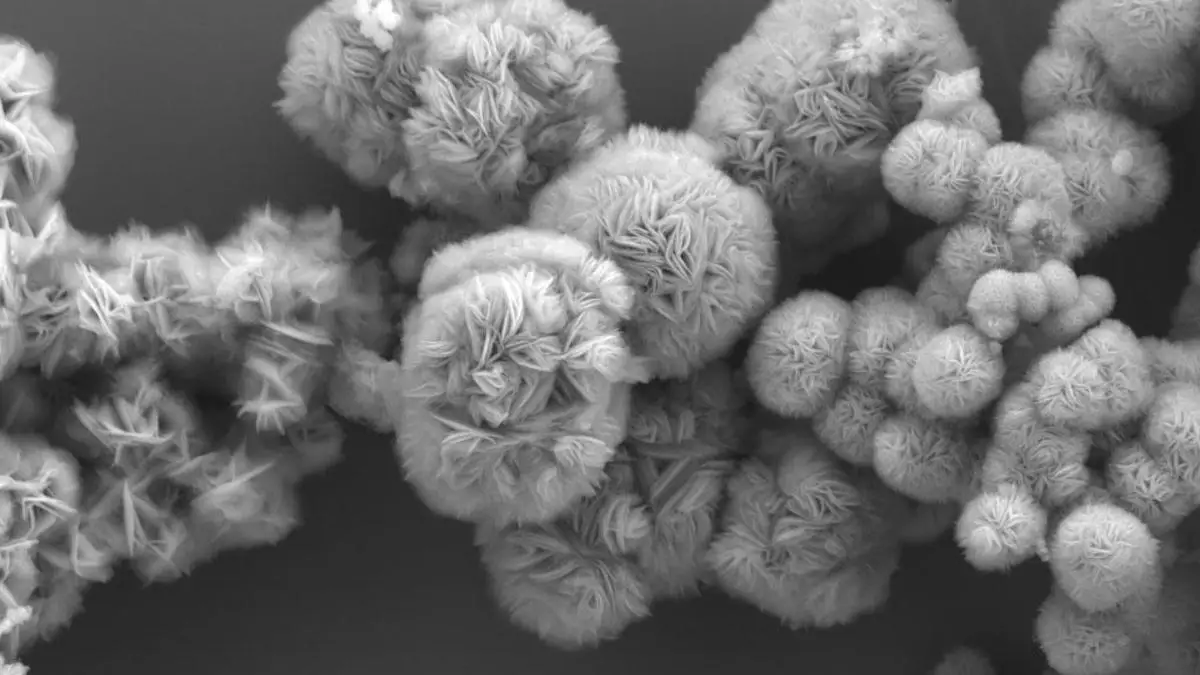

A scanning electron microscopy image reveals the beautiful shapes of tiny structures known as MXenes, which are of interest to scientists for new devices and electronics but were previously hard to create. These were grown with a new easier and less toxic method invented by chemists with the University of Chicago. For reference, the diameter of a human hair is about 50 µm. Credit: Di Wang

A cost-effective approach to producing MXene material could open up new possibilities for electronics and energy storage technology.

The key to a perfect croissant lies in its multitude of layers, with each one interspersed with butter. Similarly, a new material with potential for various applications is composed of numerous ultra-thin metal layers, between which scientists can insert different ions for specific purposes. This makes them potentially very useful for future cutting-edge electronics and energy storage.

Until recently, producing these materials, known as MXenes (pronounced “max-eens”), was as labor-intensive as creating a high-quality croissant in a traditional French bakery.

But a new breakthrough by scientists with the University of Chicago shows how to make these MXenes far more quickly and easily, with fewer toxic byproducts.

Researchers hope the discovery, published in the journal Science, will spur new innovation and pave the way towards using MXenes in everyday electronics and devices.

Atom economy

When they were discovered in 2011, MXenes made a lot of scientists very excited. Usually, when you shave a metal like gold or titanium to create atomic-thin sheets, it stops behaving like a metal. But unusually strong chemical bonds in MXenes allow them to retain the special abilities of metal, like conducting electricity strongly.

They’re also easily customizable: “You can put ions between the layers to use them to store energy, for example,” said chemistry graduate student Di Wang, co-first author of the paper along with postdoctoral scholar Chenkun Zhou.

All of these advantages could make MXenes extremely useful for building new devices—for example, to store electricity or to block electromagnetic wave interference.

However, the only way we knew to make MXenes involved several intensive chemical engineering steps, including heating the mixture at 3,000°F followed by a bath in hydrofluoric acid.

“This is fine if you’re making a few grams for experiments in the laboratory, but if you wanted to make large amounts to use in commercial products, it would become a major corrosive waste disposal issue,” explained Dmitri Talapin, the Ernest DeWitt Burton Distinguished Service Professor of Chemistry at the University of Chicago, joint appointee at Argonne National Laboratory and the corresponding author on the paper.

To design a more efficient and less toxic method, the team used the principles of chemistry—in particular “atom economy,” which seeks to minimize the number of wasted atoms during a reaction.

The UChicago team discovered new chemical reactions that allow scientists to make MXenes from simple and inexpensive precursors, without the use of hydrofluoric acid. It consists of just one step: mixing several chemicals with whichever metal you wish to make layers of, then heating the mixture at 1,700°F. “Then you open it up and there they are,” said Wang.

The easier, less toxic method opens up new avenues for scientists to create and explore new varieties of MXenes for different applications—such as different metal alloys or different ion flavorings. The team tested the method with titanium and zirconium metals, but they think the technique can also be used for many other different combinations.

“These new MXenes are also visually beautiful,” Wang added. “They stand up like flowers—which may even make them better for reactions, because the edges are exposed and accessible for ions and molecules to move in between the metal layers.”

Reference: “Direct synthesis and chemical vapor deposition of 2D carbide and nitride MXenes” by Di Wang, Chenkun Zhou, Alexander S. Filatov, Wooje Cho, Francisco Lagunas, Mingzhan Wang, Suriyanarayanan Vaikuntanathan, Chong Liu, Robert F. Klie and Dmitri V. Talapin, 23 March 2023, Science.

DOI: 10.1126/science.add9204

Graduate student Wooje Cho was also a co-author on the paper. The exploration was made possible by help from UChicago colleagues across departments, including theoretical chemist Suri Vaikuntanathan, X-ray research facility director Alexander Filatov, and electrochemists Chong Liu and Mingzhan Wang of the Pritzker School of Molecular Engineering. Electron microscopy was performed by Robert Klie and Francisco Lagunas with the University of Illinois Chicago.

Part of the research was conducted via the U.S. Department of Energy’s Advanced Materials for Energy-Water Systems, an Energy Frontier Research Center; the University of Chicago Materials Research Science and Engineering Center; and at the Center for Nanoscale Materials at Argonne National Laboratory.