Producing herbal medicines on an industrial scale is challenging. However, a team of bioengineers from Kobe University has successfully modified the cellular machinery of a specific yeast species, enabling it to produce a medicinal compound at record concentrations in a fermenter.

This breakthrough not only makes large-scale production of this molecule possible but also opens the door to microbial production of other plant-derived compounds.

Bioengineered Medicinal Compounds

Herbal medicines offer many health benefits, but they are often difficult to produce on a large scale. A good example is artepillin C—a compound with antimicrobial, anti-inflammatory, antioxidant, and anticancer properties—which is currently only available as a bee-derived product. Kobe University bioengineer Tomohisa Hasunuma explains, “To obtain a high-yield and low-cost supply, it is desirable to produce it in bioengineered microorganisms which can be grown in fermenters.” However, this approach presents technical challenges.

Challenges in Microbial Production

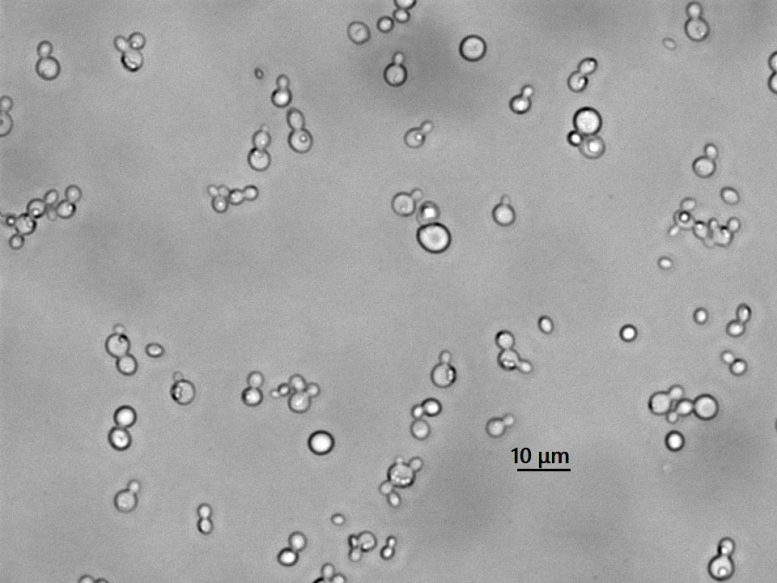

First, scientists need to identify the enzyme, or molecular machinery, that plants use to produce the target compound. “The plant enzyme that’s key to artepillin C production had only recently been discovered by Kazufumi Yazaki at Kyoto University,” Hasunuma notes. “He asked us whether we can use it to produce the compound in microorganisms due to our experience with microbial production.” The team then worked to introduce the gene responsible for this enzyme into the yeast Komagataella phaffii. Compared to brewer’s yeast, K. phaffii is better suited to produce chemicals in this class, supports higher cell densities, and doesn’t produce alcohol, which can restrict cell growth.

Achievements in Artepillin C Production

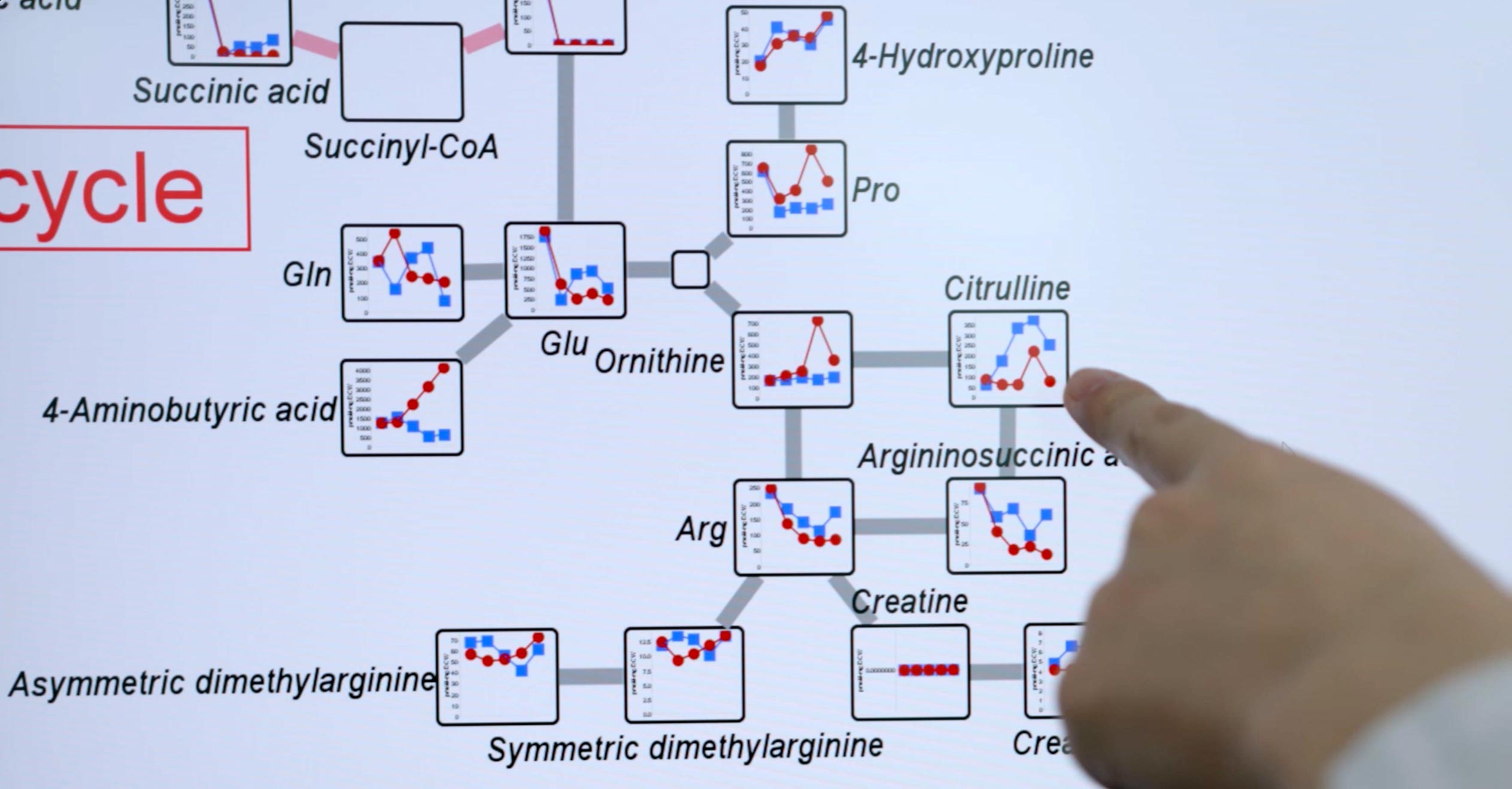

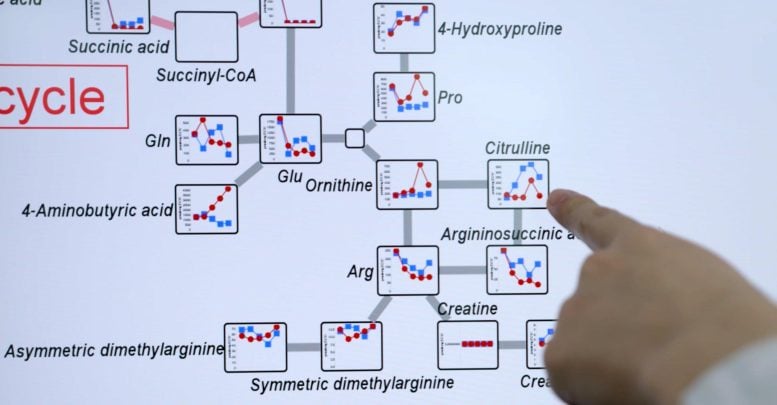

In the journal ACS Synthetic Biology, they now report that their bioengineered yeast produced ten times as much artepillin C as could be achieved before. They accomplished this feat by carefully tuning key steps along the molecular production line of artepillin C. Hasunuma adds: “Another interesting aspect is that artepillin C is not excreted into the growth medium readily and tends to accumulate inside the cell. It was therefore necessary to grow the yeast cells in our fermenters to high densities, which we achieved by removing some of the mutations introduced for technical reasons but that stand in the way of the organism’s dense growth.”

Future Prospects and Broader Implications

The Kobe University bioengineer already has ideas how to further improve the production. One approach will be to further raise the efficiency of the final and critical chemical step by modifying the responsible enzyme or by increasing the pool of precursor chemicals. Another approach may be to find a way of transporting artepillin C out of the cell. “If we can modify a transporter, a molecular structure that transports chemicals in and out of cells, such that it exports the product into the medium while keeping the precursors in the cell, we could achieve even higher yields,” Hasunuma says.

The implications of this study, however, go beyond the production of this particular compound. Hasunuma explains, “Since thousands of compounds with a very similar chemical structure exist naturally, there is the very real possibility that the knowledge gained from the production of artepillin C can be applied to the microbial production of other plant-derived compounds.”

Reference: “De novo production of the bioactive phenylpropanoid artepillin C using membrane-bound prenyltransferase in Komagataella phaffii” 12 November 2024, ACS Synthetic Biology.

DOI: 10.1021/acssynbio.4c00472

This research was funded by the Japan Society for the Promotion of Science (grant 23H04967), the RIKEN Cluster for Science, Technology and Innovation Hub and the Japan Science and Technology Agency (grant JPMJGX23B4). It was conducted in collaboration with researchers from Kyoto University and the RIKEN Center for Sustainable Resource Science.