A study reveals the influence of grain boundaries on materials, showing how iron levels change icosahedral structures and affect material properties.

Through microscopy and simulations, researchers aim to design materials with improved durability.

Grain Boundaries and Material Performance

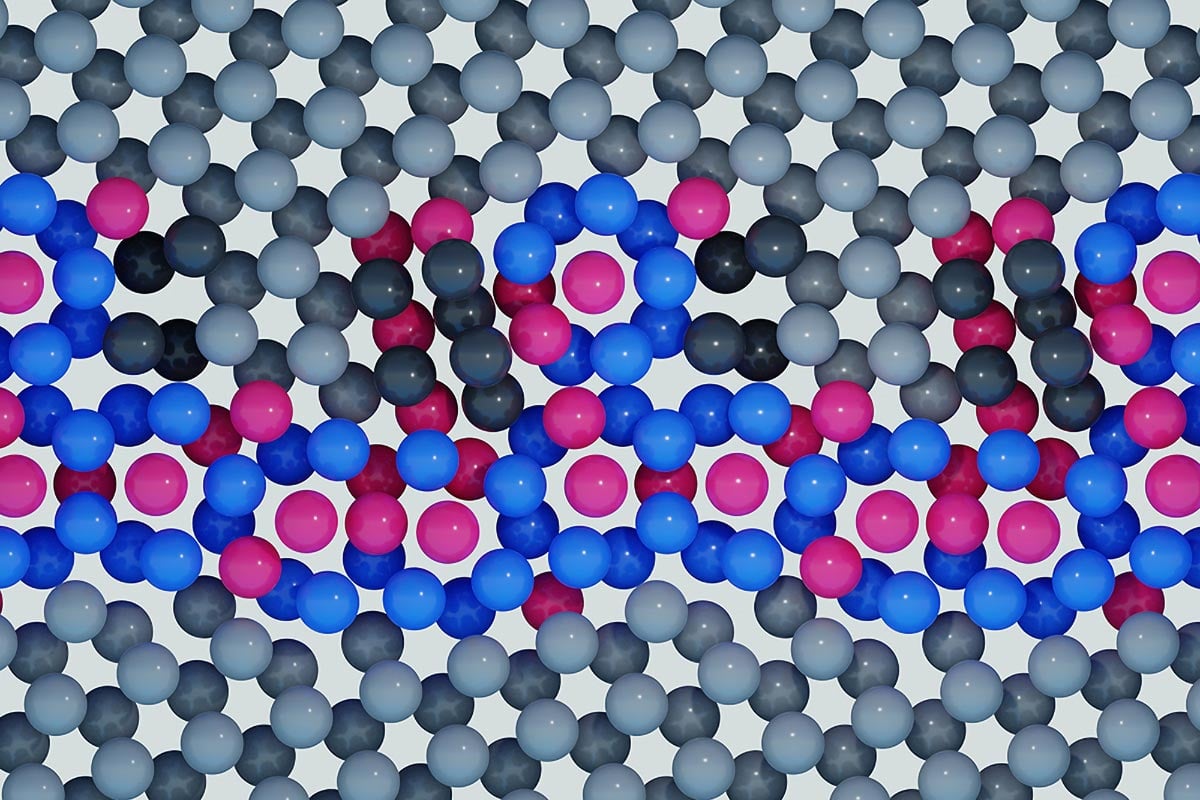

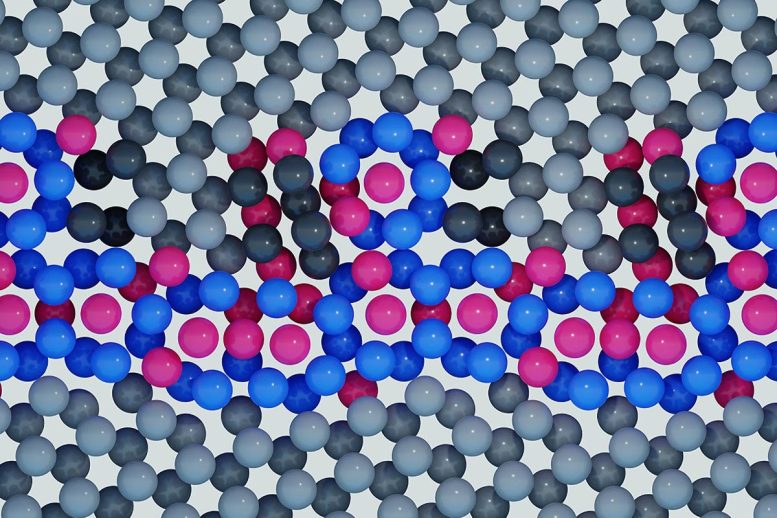

Most technological materials have a polycrystalline structure, meaning they consist of multiple crystals with atoms arranged in a regular lattice. These crystals are not aligned in the same direction throughout the material, and the interfaces between them are called grain boundaries.

“These grain boundaries have an enormous influence on the durability and overall performance of a material,” explains Dr. Vivek Devulapalli, who conducted the microscopy work for the study. He adds, “But we have very limited understanding what happens when elements segregate to grain boundaries and how they influence the properties of a material.”

Advanced Techniques in Material Analysis

The breakthrough in this research was the ability to observe and model these structures at an atomic level. By combining high-resolution scanning transmission electron microscopy with advanced computer simulations, the researchers could study the grain boundaries in unprecedented detail. A newly developed prediction algorithm accurately reproduced the observed grain boundary structures, allowing researchers to analyze them more effectively.

“Our simulations show that for different iron contents, we always find the cage structures as the underlying building blocks of different grain boundary phases. As the iron level increases at the grain boundary, more icosahedral units appear and eventually agglomerate,” explains Dr. Enze Chen from Stanford University. An icosahedron, in this context, is a geometric shape with 12 vertices, or points occupied by atoms, and 20 faces.

“We have identified more than five distinct structures or grain boundary phases of the same boundary, all composed of different arrangements of the same icosahedral cage units,” adds Dr. Timofey Frolov who was leading the computational work of the study.

Insights Into Icosahedral Structures

A closer inspection of the cage structures revealed that the atoms adopt an icosahedral arrangement with iron atoms being located at the center of the icosahedron and titanium atoms occupying its vertices.

“The icosahedral cages enable a dense packing of iron atoms and since they can form aperiodic clusters, more than two to three times the amount of iron can be accommodated at the grain boundary,” explains Vivek Devulapalli.

“It appears as if iron is trapped inside of quasicrystalline-like grain boundary phases,” adds Chen.

“This is attributed to the properties of the icosahedral cages,” says Liebscher, “and we now need to find ways to study how they influence the interface properties and with this the material behavior.”

Exploring Material Design Through Grain Boundary Phases

Understanding and controlling the formation of icosahedral grain boundary phases with different structures and properties can potentially be used to tailor the properties of materials. The researchers now want to systematically investigate how these novel grain boundary states can be used to tune material behavior, adjust a certain material functionality, and make materials more resilient against degradation processes.

Reference: “Topological grain boundary segregation transitions” by Vivek Devulapalli, Enze Chen, Tobias Brink, Timofey Frolov and Christian H. Liebscher, 24 October 2024, Science.

DOI: 10.1126/science.adq4147