Unlock the Editor’s Digest for free

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Tariffs on Chinese-made electric cars are pushing carmakers to consider opening new plants in the US and the EU to avoid duties. But trade restrictions may also start a new trend of automakers assembling electric vehicles overseas — opening up new markets in the process.

Geely Auto plans to assemble cars in Vietnam, as it invests to expand production in the south-east Asian country. The Chinese carmaker will build a plant in Vietnam capable of producing 75,000 cars a year in a joint venture with Hanoi-based Tasco Joint Stock Company, it said on Tuesday.

There has been growing interest in using so-called knockdown kit assembly plants to make EVs for export as Chinese makers face stricter trade barriers on the country’s EVs. The move by Geely, which is China’s second-largest automaker by sales after BYD and owns Volvo Cars as well as stakes in Aston Martin and Mercedes-Benz, should mean more local rivals should follow.

The decision for Chinese EV makers is which part of the manufacturing process to shift overseas. When it comes to deciding between making EV components overseas or assembly, the latter would seem the safer bet for companies that want to protect proprietary technology

Knockdown kit assembly plants are set up overseas with the EV maker shipping a large amount of parts to be put together into the final product. These types of plants are less expensive to set up and operate than those that make components because they do not need to be automated, relying on local labour for assembly.

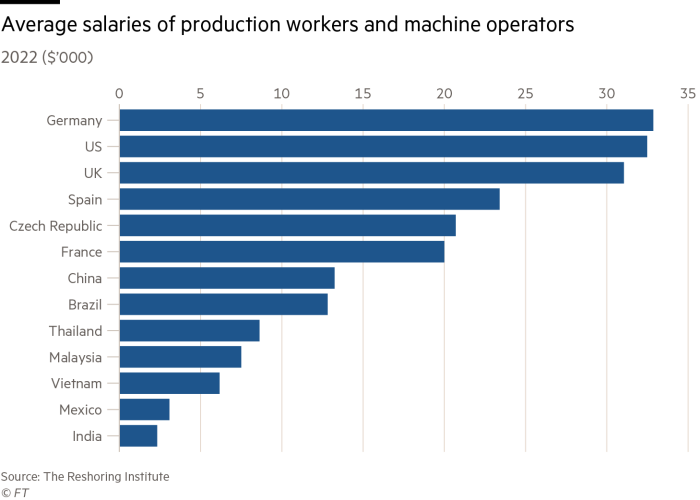

The growth in Chinese labour costs over the past decade has outpaced many regional peers. Vietnam’s labour costs are on average about half that of China. For industries that need scale, such as smartphone assembly, Vietnam’s labour force, which is about 7 per cent the size of China’s, would be too small to provide a viable alternative. But for EVs this set-up makes sense.

The added benefit of outsourcing assembly is that Chinese EV makers may be able to receive tax benefits for creating local manufacturing jobs in the country they set up in, and also through investments through local joint ventures, as is the case with Geely in Vietnam.

Shares of Geely Automobile Holdings are up 40 per cent from their August low, with BYD up a third this year despite looming tariffs. Shifting assembly out of China will not help completely avoid duties: in markets such as the US, a duty is also levied on imported components such as batteries and key metals. But it should mean an export boost for new markets, especially those in which they set up these assembly plants.