Europe’s transition to electric cars is under threat because of persisting shortages of lithium, the key battery component that will power the vehicles of the future.

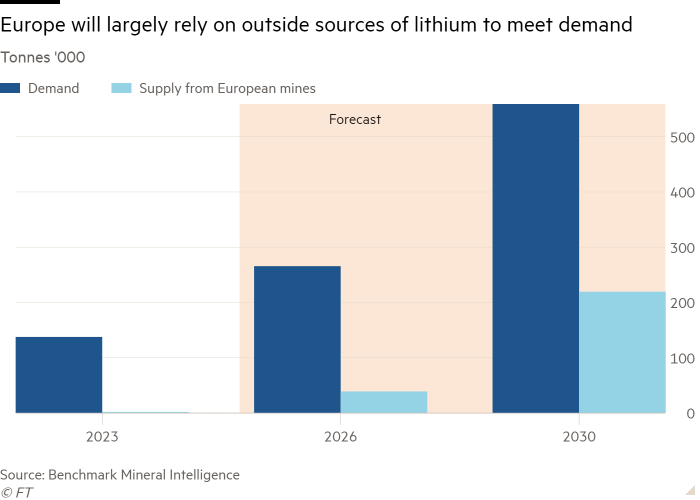

EU plans to ban sales of new petrol and diesel cars by 2035 mean demand for lithium is set to surge fivefold by 2030 to 550,000 tonnes per year — more than double the 200,000 tonnes the region will be able to produce, according to Benchmark Mineral Intelligence.

“The whole global market is still set to be in a deficit by the end of the decade,” said Daisy Jennings-Gray, analyst at Benchmark Mineral Intelligence.

“Europe will probably sit in a tight position in terms of availability and cannot afford any delays to domestic projects [to extract the metal].”

The supply problem has been highlighted by the world’s largest lithium producer Albemarle, which has sidelined plans to extract lithium in Europe after failing to find a commercially viable site.

“The resources we are aware of in Europe are not high quality and relatively small,” the group’s chief financial officer Scott Tozier told the Financial Times.

The projected lithium deficit in a market already suffering global shortages and high prices of $62,000 per tonne — more than five times the average cost of production despite a recent drop — may prove existential for European carmakers.

Without a homegrown supply of the battery gold, Europe’s auto groups could find it difficult to compete with China, which is rapidly expanding its electric car industry and making inroads into the European market.

A sign of China’s dominance in the field is that it controls 60 per cent of global lithium processing, which turns a concentrate produced from brine or ore into lithium chemical compounds such as carbonate or hydroxide that are used in car batteries.

Francis Wedin, chief executive of Australian-listed Vulcan Energy Resources, one of the few companies trying to extract lithium in Europe, said the region’s car industry would not be able to electrify its future fleet without its own lithium.

China “will prioritise supply for its own industry”, he said. Without its own access to lithium, European carmakers would “not survive competition” from the country, he added.

Although US-based Albemarle, which supplies a fifth of the world’s lithium, plans to build a European refinery for the metal by the end of the decade, carmakers need alternatives now.

That has prompted some leading European car groups to gamble on a handful of local projects, where success is far from assured because of the complicated extraction processes.

One involves Perth-based Vulcan, which is promising to extract lithium out of German brine using geothermal power.

Opel-maker Stellantis last year became the first carmaker to invest in a lithium miner when it paid €50mn in return for equity in Vulcan. Renault and Volkswagen have, much like Stellantis, also made binding orders for Vulcan’s expected supply of lithium.

Another risky project involves French mining group Imerys, which aims to extract lithium from rocks underneath a kaolin mine, opened by the country’s ceramics industry in the 19th century.

Vulcan hopes to produce 24,000 tonnes annually two years after starting production in 2025 while Imerys is planning to start producing 34,000 tonnes of battery-grade lithium chemicals a year from 2028.

Combined, this is enough to supply roughly 1.2mn small electric vehicle batteries a year, according to the companies’ calculations.

But this is a long way short of expected demand for electric cars, which is likely to match or exceed current sales volumes with 11.3mn new cars registered in Europe in 2022, according to German trade group VDA.

This also assumes the success of the Vulcan and Imerys ventures.

“The projects carry an inherent risk as we are daring production processes that nobody has done before,” admitted Alessandro Dazza, chief executive of Imerys, as he highlighted the need for government support.

In addition, there is a danger the ventures will end up costing far more than rival projects.

Vulcan needs to put down nearly twice as much money upfront than many of its rivals, as it must build geothermal plants before it can start the extraction process.

Its method involves pumping up hot lithium-rich brines from underground wells. The heat from the brine creates geothermal energy that can be used to extract the lithium, as well as heat nearby communities, reducing its carbon footprint.

Its capital expenditure exceeds $30,000 per tonne of production capacity compared with an average of $17,300 for just over 50 of the world’s leading lithium projects, according to S&P Global and Scotiabank.

Analysts at S&P say the higher cost for some projects is because they involve on-site processing of the material to the high grade needed for batteries, which Vulcan hopes to do.

Vulcan also argues that its production costs, once the plant is built, will be unusually low with operational expenses estimated at €4,000-€4,500 per tonne.

That claim, however, has been met with some investor scepticism. Nearly 7 per cent of Vulcan’s shares on the Australian Securities Exchange have been shorted — a bet on the share price falling.

The company has also pushed back the timeline for its first production by a year to 2025, which is not an uncommon fate with the average lithium project being delayed by three years against original expectations, according to Canaccord Genuity.

The EU is aware of the problems. Its Critical Raw Materials Act aims to shore up its EV supply chain by sourcing more battery metals such as lithium, cobalt and nickel domestically.

But executives say financial support from governments is needed to get domestic lithium supply off the ground.

Europe also needs to address bureaucratic hurdles, such as arduous procedures for processing permits, as well as political and local resistance to mining.

It can take years for some mining companies to get their environmental permits once all the studies have been submitted. The EU wants to impose a 24-month deadline to address this.

Rio Tinto’s Jadar project in Serbia, which would have created one of the world’s largest lithium mines, was one of the casualties of the system. Its exploration and development licences were revoked ahead of elections last year because of environmental concerns and political opposition.

But even without permitting delays, analysts say the challenges ahead for Europe in meeting lithium needs are enormous, particularly when compared with the US that has put vast resources behind disentangling its critical mineral supply chains from China.

“It’s a one-two punch for the extractive sector in Europe of a lack of money going in at the early stage of exploration and a much more difficult permitting environment than Africa, Australia and Canada,” said Kevin Murphy, analyst at S&P Global Commodities.

“In the near term, Europe will be heavily reliant on outside resources to supply their industry.”